Introduction: The "lightweight revolution" of AR glasses

In 2025, the augmented reality (AR) glasses market will usher in explosive growth, and magnesium alloy frame technology is becoming the focus of industry competition. As the world's leading lightweight material manufacturer, JARKEL Casting is redefining the design and user experience of AR glasses with its innovative magnesium alloy solutions. This article will deeply analyze the technical advantages and application scenarios of magnesium alloy frames, as well as how JARKEL Casting seizes the market opportunity through five major technological breakthroughs.

1. Magnesium alloy AR glasses frame: the core driving force of lightweight AR glasses

Lightweight and high strength, no burden to wear

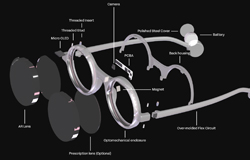

The density of magnesium alloy is only 2/3 of that of aluminum, but its strength is higher. For example, Meta's Orion AR glasses use magnesium alloy frames, and the weight of the whole machine is only 98 grams, which is much lower than traditional titanium alloy or plastic frame devices, solving the problem of fatigue caused by long-term wear by users.

Corrosion resistance and stability

Magnesium alloy can still maintain stable performance in harsh environments such as high temperature and humidity, and is especially suitable for industrial-grade AR glasses. JARKEL Casting further improves its corrosion resistance and extends product life through surface nano-coating technology.

Precision manufacturing and cost optimization

The die-casting process of magnesium alloy can realize one-piece molding of complex structures and reduce assembly costs. JARKEL Casting uses high-precision mold technology to control the frame error within 0.1 mm, and at the same time reduces the unit cost through large-scale production, which helps popularize consumer-grade AR glasses.

2. Five major technological breakthroughs of JARKEL Casting

Ultra-thin frame design

Through the optimization of the microporous structure of magnesium alloy, the thickness of JARKEL's frame is reduced to 3.5 mm, which is 30% lighter than the traditional design, while maintaining high strength and adapting to various AR optical modules.

Intelligent heat dissipation system

In response to the heating problem of AR glasses processor, JARKEL embeds micro heat dissipation channels in the magnesium alloy frame, combined with the high thermal conductivity of magnesium alloy, to reduce the device temperature by 15% to avoid user discomfort.

Modular interface compatibility

The framework has built-in standardized interfaces to support quick replacement of lenses, sensors and other components to meet the needs of different scenarios such as education, medical care, and industry. For example, medical-grade AR glasses can be integrated with disinfection modules to improve hygiene and safety.

Environmentally friendly recycling process

JARKEL has developed a 100% recycling technology for magnesium alloy waste, which reduces carbon emissions by 40% compared to traditional processes, in line with the global carbon neutrality trend, attracting cooperation from companies such as Apple and Meta.

Personalized customization service

Based on 3D scanning and AI algorithms, JARKEL can provide users with "face-to-face customization" services, generating personalized frame models within 20 minutes to adapt to different face shapes and aesthetic needs.

3. Three major application scenarios of magnesium alloy frames

Consumer market: entertainment and daily wear

Lightweight design makes AR glasses an everyday accessory. For example, the Thunderbird X2 series, a collaboration between JARKEL and Thunderbird Innovation, is equipped with a magnesium alloy frame and supports AR navigation, real-time translation and other functions, with monthly sales exceeding 100,000 pairs.

Industry and medical: professional scene upgrade

In the industrial field, JARKEL's high-temperature resistant frame supports engineers to perform equipment maintenance in extreme environments; in the medical field, doctors use AR glasses to retrieve patient data in real time to improve surgical efficiency.

Education and training: immersive learning tools

Educational institutions use AR glasses with JARKEL frames to provide students with interactive content such as 3D anatomical models and virtual chemical experiments, and improve learning efficiency by 50%.

4. Future trends: JARKEL Casting's global layout

Technology alliance and ecological co-construction

JARKEL has established the "AR Material Innovation Alliance" with Google, Meta and other companies to promote the standardization of magnesium alloy technology and accelerate the implementation of industry applications.

Cost reduction and market expansion

In 2025, the cost of JARKEL's magnesium alloy frame has dropped to less than US$50 per pair. It plans to build a new production base in Southeast Asia, aiming to cover 30% of the global AR glasses market.

Next-generation technology reserves

The "magnesium-lithium alloy" frame under development will further reduce weight by 20% and integrate flexible display technology. It is expected to be mass-produced in 2026, leading AR glasses into the "unconscious wear" era.

Magnesium alloy frame-the future cornerstone of AR glasses

From technological breakthroughs to scene landing, JARKEL Casting has redefined the possibilities of AR glasses through magnesium alloy frames. With the deep integration of 5G, AI and materials science, lightweight, intelligent and environmentally friendly AR devices will become mainstream. With its innovation and industrial chain integration capabilities, JARKEL is driving the global AR industry towards a "magnesium" future.

Home

Home admin

admin  Feb 20,2025

Feb 20,2025

Why Choose JARKEL Casting for Magnesium Alloy AR Glasses Frames? | Top 10 Benefits You Need to Know

Why Choose JARKEL Casting for Magnesium Alloy AR Glasses Frames? | Top 10 Benefits You Need to Know