The augmented reality (AR) industry is booming, and AR glasses are at the forefront of this technological revolution. Magnesium alloy has emerged as the preferred material for AR glasses frames due to its lightweight, durability, and flexibility. However, customizing magnesium alloy frames requires careful planning and attention to detail. In this article, we’ll explore the key factors to consider when customizing magnesium alloy AR glasses frames and highlight why JARKEL Casting is the ideal partner for your precision manufacturing needs.

Why Customize Magnesium Alloy AR Glasses Frames?

Customization allows brands to create AR glasses frames that meet specific design, functional, and branding requirements. Magnesium alloy is particularly suited for customization due to its:

Lightweight Nature: Reduces user fatigue during extended wear.

High Strength: Ensures durability and longevity.

Malleability: Allows for complex designs and precise detailing.

Corrosion Resistance: Maintains the frame’s appearance and functionality over time.

By working with an experienced manufacturer like JARKEL Casting, you can leverage these properties to create frames that stand out in the competitive AR market.

Key Considerations When Customizing Magnesium Alloy AR Glasses Frames

Customizing magnesium alloy AR glasses frames involves several critical factors. Here’s what you need to consider:

1. Design Requirements

Ergonomics: Ensure the frame fits comfortably on the user’s face.

Aesthetics: Create a visually appealing design that aligns with your brand identity.

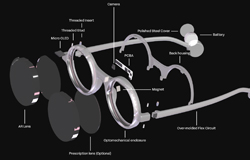

Functionality: Design the frame to accommodate components like lenses, sensors, and electronics.

2. Material Selection

Grade of Magnesium Alloy: Choose the right alloy grade based on strength, weight, and corrosion resistance requirements.

Surface Finish: Decide on finishes like anodizing, powder coating, or polishing to enhance durability and appearance.

3. Precision Manufacturing

Casting Techniques: Use advanced methods like die casting or CNC machining for high precision.

Tolerances: Ensure tight tolerances for a perfect fit of all components.

4. Weight Optimization

Thickness and Structure: Balance weight and strength by optimizing the frame’s structure.

Material Distribution: Ensure even weight distribution for comfort and stability.

5. Integration with AR Components

Mounting Points: Design frames to securely hold lenses, sensors, and other AR components.

Thermal Management: Incorporate features to dissipate heat from electronic components.

6. Custom Branding

Logos and Engravings: Add custom logos or engravings to enhance brand recognition.

Color Options: Offer a range of colors to meet customer preferences.

7. Scalability and Lead Times

Prototyping: Test designs with prototypes before mass production.

Production Volume: Ensure the manufacturer can handle both small and large orders.

Delivery Timelines: Confirm realistic lead times to meet project deadlines.

8. Cost Efficiency

Material Costs: Optimize material usage to reduce costs.

Manufacturing Process: Choose cost-effective techniques without compromising quality.

9. Sustainability

Eco-Friendly Materials: Use recyclable magnesium alloys.

Sustainable Practices: Partner with manufacturers that prioritize energy efficiency and waste reduction.

10. Certifications and Compliance

Quality Standards: Ensure the frames meet ISO, RoHS, or other relevant certifications.

Safety and Durability: Test frames for safety and durability under various conditions.

Why Choose JARKEL Casting for Custom Magnesium Alloy AR Glasses Frames?

JARKEL Casting is a trusted name in precision manufacturing, offering unparalleled expertise in customizing magnesium alloy AR glasses frames. Here’s why they stand out:

Expertise in Magnesium Alloy

With years of experience, JARKEL Casting has mastered the art of working with magnesium alloy, ensuring high-quality, lightweight, and durable frames.

Advanced Manufacturing Technologies

Their state-of-the-art facilities include CNC machining, 3D modeling, and precision casting, enabling them to deliver complex designs with unmatched accuracy.

Comprehensive Customization Options

From ergonomic designs to custom branding, JARKEL Casting offers a wide range of customization options to meet your specific needs.

Rigorous Quality Control

Every frame undergoes stringent quality checks to ensure it meets the highest industry standards.

Scalable Production

Whether you need prototypes or mass production, JARKEL Casting can handle orders of any size.

Sustainable Practices

They are committed to eco-friendly manufacturing processes and use recyclable materials to minimize environmental impact.

Global Reach

With a robust logistics network, JARKEL Casting ensures timely delivery to clients worldwide.

Applications of Custom Magnesium Alloy AR Glasses Frames

Custom magnesium alloy frames are used in various industries, including:

Consumer AR Glasses: Lightweight and stylish frames for everyday use.

Industrial AR Glasses: Durable frames for demanding environments.

Medical AR Glasses: Precision-engineered frames for healthcare applications.

Gaming AR Glasses: Comfortable and ergonomic frames for extended use.

The Future of Custom Magnesium Alloy AR Glasses Frames

As AR technology advances, the demand for customizable, lightweight, and durable frames will continue to grow. Magnesium alloy, with its exceptional properties, is poised to remain the material of choice for AR glasses frames. JARKEL Casting is at the forefront of this industry, leveraging its expertise to deliver innovative solutions.

Why Partner with JARKEL Casting?

Choosing the right partner is crucial for the success of your AR glasses. Here’s why JARKEL Casting is the ideal choice:

Proven Track Record: A history of delivering high-quality products to clients worldwide.

Innovative Solutions: A team of experts dedicated to pushing the boundaries of what’s possible.

Customer-Centric Approach: Working closely with clients to understand their needs and deliver tailored solutions.

Conclusion

Customizing magnesium alloy AR glasses frames involves careful consideration of design, materials, manufacturing techniques, and compliance. By partnering with JARKEL Casting, you can ensure your frames meet the highest standards of quality, functionality, and aesthetics. Their expertise and commitment to excellence make them the ideal choice for businesses looking to create cutting-edge AR glasses frames.

JARKEL Casting is not just a manufacturer; it’s a partner in innovation. Contact them today to learn more about their custom magnesium alloy AR glasses frame solutions and take your product to the next level!

Home

Home admin

admin  Feb 19,2025

Feb 19,2025

How will magnesium alloy AR glasses frames change the industry in 2025? JARKEL Casting's five major technological breakthroughs and market opportunities

How will magnesium alloy AR glasses frames change the industry in 2025? JARKEL Casting's five major technological breakthroughs and market opportunities