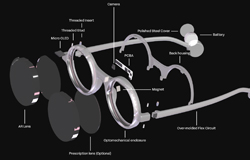

With the rapid development of augmented reality (AR) technology, AR glasses have gradually become a popular product in the consumer electronics market. However, the choice of frame material for AR glasses is crucial to the product's lightweight, durability and user experience. As a world-leading magnesium alloy casting expert, JARKEL Casting has launched an innovative magnesium alloy AR glasses frame solution, setting a new benchmark for the industry

Magnesium alloy: an ideal material for AR glasses frames

AR glasses, as a wearable device, have extremely high requirements for the lightweight, strength and durability of materials. Magnesium alloy has become an ideal choice for AR glasses frames due to its unique performance advantages:

1. Lightweight: The density of magnesium alloy is only 1.74 g/cm³, which is one of the lightest materials among commonly used metals. It can significantly reduce the overall weight of AR glasses and improve wearing comfort.

2. High strength: The specific strength (ratio of strength to density) of magnesium alloy is higher than that of aluminum alloy and steel, which can provide sufficient structural support for AR glasses.

3. Corrosion resistance: Through advanced surface treatment technology, magnesium alloy can have excellent corrosion resistance and extend the service life of the product.

4. Electromagnetic shielding: Magnesium alloy has good electromagnetic shielding performance, which can effectively protect the electronic components inside AR glasses from interference.

5. Environmental protection and recyclability: Magnesium alloy can be fully recycled, which is in line with the concept of sustainable development.

With many years of experience in magnesium alloy research and development, JARKEL Casting has successfully applied magnesium alloy to the manufacture of AR glasses frames, providing users with lighter, stronger and more durable solutions.

JARKEL Casting's magnesium alloy AR glasses frame solution

JARKEL Casting's magnesium alloy AR glasses frame solution covers the entire process from material research and development, design optimization to precision manufacturing, ensuring high-quality products for customers.

1. Material research and development and optimization

JARKEL Casting has an advanced magnesium alloy research and development laboratory, which can customize and develop high-performance magnesium alloy materials according to customer needs. By adjusting the alloy composition and optimizing the heat treatment process, JARKEL Casting's magnesium alloy materials have reached the industry-leading level in strength, toughness and corrosion resistance.

2. Structural design and simulation

JARKEL Casting's engineering team uses advanced computer-aided design (CAD) and finite element analysis (FEA) technologies to optimize the structure of the AR glasses frame. Through simulation analysis, it is ensured that the frame has sufficient strength and stability while being lightweight.

3. Precision casting process

JARKEL Casting uses advanced processes such as high-pressure die casting (HPDC) and semi-solid forming to ensure the dimensional accuracy and surface quality of the magnesium alloy frame. Its precision casting technology can achieve the molding of complex structures and meet the high-precision requirements of AR glasses frames.

4. Surface treatment and decoration

In order to enhance the aesthetics and durability of the magnesium alloy frame, JARKEL Casting provides a variety of surface treatment solutions, including anodizing, micro-arc oxidation, spraying and electroplating. These processes not only enhance the corrosion resistance of the frame, but also provide users with a variety of appearance options.

5. Quality Inspection and Certification

JARKEL Casting strictly implements the ISO 9001 quality management system and conducts comprehensive quality inspections on each batch of magnesium alloy frames, including dimensional measurement, strength testing and corrosion resistance testing, to ensure that the products meet international standards.

Market advantages of JARKEL Casting solutions

JARKEL Casting's magnesium alloy AR glasses frame solution has significant advantages in the market:

1. Lightweight design: Compared with traditional materials, magnesium alloy frames can reduce weight by 30%-50%, significantly improving wearing comfort.

2. High cost performance: JARKEL Casting has reduced the manufacturing cost of magnesium alloy frames through large-scale production and process optimization, providing customers with cost-effective options.

3. Fast delivery: JARKEL Casting has a complete production supply chain, which can quickly respond to customer needs and shorten product delivery cycles.

4. Customized service: JARKEL Casting provides full-process customized services from material selection to surface treatment to meet customers' personalized needs.

Successful Case: JARKEL Casting cooperates with the world's leading AR brands

JARKEL Casting has reached cooperation with many of the world's leading AR glasses brands to provide them with magnesium alloy frame solutions. For example, after adopting JARKEL Casting's magnesium alloy frame, the product weight was reduced by 40%, and the strength and durability of the frame were significantly improved, which was highly praised by users.

Future Outlook: JARKEL Casting promotes innovation in the AR glasses industry

With the continuous advancement of AR technology, the application scenarios of AR glasses will be more extensive. JARKEL Casting will continue to deepen the research and development of magnesium alloy materials and manufacturing process innovation to provide better solutions for the AR glasses industry. In the future, JARKEL Casting plans to cooperate with more AR brands to jointly promote technological progress and product upgrades in the industry.

JARKEL Casting's magnesium alloy AR glasses frame solution is becoming a new standard in the industry with its advantages such as lightweight, high strength and durability. If you are looking for a high-performance and cost-effective AR glasses frame material, JARKEL Casting will be your best choice. Contact us now to learn more about the magnesium alloy AR glasses frame solution!

Home

Home admin

admin  Feb 15,2025

Feb 15,2025

Analysis of the 4 core advantages: How JARKEL Casting reshapes the customization standards of magnesium alloy AR glasses frames

Analysis of the 4 core advantages: How JARKEL Casting reshapes the customization standards of magnesium alloy AR glasses frames