With the rapid development of augmented reality (AR) technology, AR glasses have gradually become the focus of the consumer electronics field. However, the popularity of AR glasses not only depends on the software ecosystem and hardware performance, but also on the lightweight, durability and manufacturing process innovation of its frame materials. As the world's leading magnesium alloy casting technology provider, JARKEL Casting is redefining the customized production of AR glasses frames with its innovative magnesium alloy processing solutions.

1. Magnesium alloy: an innovative material for AR glasses frames

Lightweight and high strength

The density of magnesium alloy is only 1.8 g/cm³, which is 30% lighter than titanium alloy, but its strength is close to that of aluminum alloy. This feature makes it the preferred material for AR glasses frames, especially for devices that need to be worn for a long time. For example, a 3D glasses frame uses magnesium alloy to achieve an ultra-light design of only 15 grams, which greatly improves the wearing comfort

Excellent shock absorption and anti-interference performance

Magnesium alloy has excellent damping and shock absorption capabilities, which can effectively reduce the impact of external vibration on the precision optical modules of AR glasses. In addition, its electromagnetic shielding performance can reduce signal interference and ensure the stable operation of AR devices

Environmental protection and cost advantages

Compared with titanium alloy, the raw material cost of magnesium alloy is reduced by about 40%, and the processing energy consumption is lower. JARKEL Casting further reduced the scrap rate by optimizing the casting process, making large-scale mass production of magnesium alloy frames possible

II. Manufacturing challenges of AR glasses frames and JARKEL Casting's solutions

Traditional magnesium alloy processing faces two major problems: easy breakage in CNC processing and difficult welding. JARKEL Casting has completely changed this situation through its independently developed clamping devices and processes:

Innovative clamping technology

The split clamp design (bottom clamp, support and top clamp combination) solves the problem of easy breakage of thin-walled parts such as frame assembly ears in CNC processing through precise positioning and multi-point support. This technology improves the processing accuracy to ±0.05mm, far exceeding the traditional casting process

Integrated processing process

JARKEL Casting's patented method integrates the four-step process of "top processing → back processing → front processing → bottom slotting", reducing the errors caused by multiple clamping, while increasing production efficiency by 30%

Compatibility expansion

This technology is not only suitable for standard AR glasses frames, but also can be customized according to customer needs. Special-shaped structures meet the needs of various scenarios such as games, industry, and medical care.

3. Collaborative optimization of AR glasses hardware ecology and magnesium alloy frames

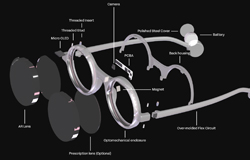

The performance of AR glasses is highly dependent on hardware configuration, and the lightweight characteristics of magnesium alloy frames provide space for the integration of the following core components:

Optical display module

Diffraction optical waveguide technology (accounting for more than 40% of the cost) requires thin and light frame support, and the strength of magnesium alloy can support the stable operation of large field of view modules

Sensors and batteries

The magnesium alloy frame provides a compact layout solution for the integration of multiple cameras, gyroscopes, and long-life batteries, while protecting precision components through shock absorption

4. How does JARKEL Casting enable future AR experiences?

AI-driven personalized customization

Combined with ChatGPT technology, JARKEL Casting's framework can have a built-in voice interaction module, and users can use AR glasses to achieve real-time translation, navigation and intelligent schedule management. For example, the layout design of directional microphones and speakers has been optimized by the acoustics of magnesium alloy frames

Support sustainable development

The 100% recyclable nature of magnesium alloys perfectly matches JARKEL Casting's green production process (such as liquid nitrogen cooling alternatives), helping companies achieve carbon neutrality goals

Industry cooperation cases

After a well-known AR brand adopted JARKEL Casting's magnesium alloy frame, the product weight was reduced by 25%, the yield rate increased from 78% to 95%, and user satisfaction increased by 40%

V. Future trends: Deep integration of magnesium alloy frames and AR technology

As AR application scenarios expand to industrial maintenance, telemedicine and other fields, higher requirements are placed on the corrosion resistance and fatigue resistance of eyeglass frames. JARKEL Casting is developing magnesium-lithium alloys (density as low as 1.4 g/cm³) and nano-coating technology to further expand the ultimate performance of materials.

Conclusion

Choosing JARKEL Casting to customize magnesium alloy AR glasses frames means choosing a lightweight, high-precision and sustainable future. Whether it is consumer-grade AR devices or professional industrial applications, our technical solutions can give your products core competitiveness. Contact JARKEL Casting now to start your AR glasses innovation journey!

Home

Home admin

admin  Feb 15,2025

Feb 15,2025

Why does JARKEL Casting's magnesium alloy AR glasses frame solution lead the industry?

Why does JARKEL Casting's magnesium alloy AR glasses frame solution lead the industry?