Lightweight

Magnesium alloy is one of the lightest metal structural materials currently, which can significantly reduce the wearing burden of AR glasses and improve user experience.

High Strength

The high strength and rigidity of magnesium alloy ensure that AR glasses are not easily deformed or damaged in daily use.

Excellent Physical Properties

Magnesium alloy's corrosion resistance, thermal conductivity, electromagnetic shielding.

Comfort

Emphasize the skin-friendliness and good touch of magnesium alloy to improve wearing comfort.Processing Technology Advantages

The machining process of magnesium alloy AR glasses frames mainly includes die casting and semi-solid injection molding.

Die-casting Technology

Semi-solid Injection Molding

Semi-solid injection molding has the advantages of low porosity, long mold life and stable filling quality compared with die casting.

Low Porosity

Long Mold Life

Stable Filling Quality

Higher Precision and More Complex Design

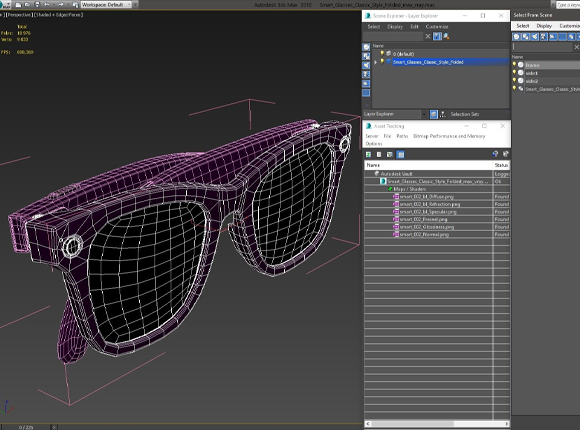

They Look Almost Like a Normal Pair of Glasses

The term "smart glasses" can refer to many different things you can wear on your face, from augmented reality (AR) displays to live-streaming cameras to voice assistant-equipped headphones, all built into a pair of specs. We particularly like the AR glasses, which connect with your phone or computer and project a personal display in front of your eyes.

Customized Service

Emphasis that you can provide customized design and production services according to customer needs.

Including: Appearance Design Structural Design Surface Treatment

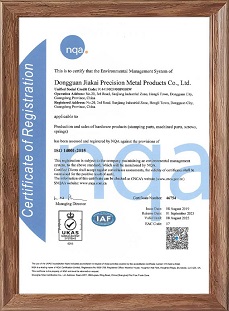

Quality -Ease of Compliance

Responsibility to minimize the environmental impact by applying green production, complying with RoHS and REACH legislation. We are also approved to meet environmental management standards, IS0 9001 quality.

IATF16949

ISO9001

ISO13485

ISO14001

ISO27001

Dongguan Jiakai Precision Metal Products Co., Ltd.

Established in 2002, we have ben operating for more than 22 years so far, and are a high-tech enterprise speciazing in precision hardware products. The company has been certified by 1s0901,15014000,15S013485, 1S045001, QC08000 and lATF16949. With more than 400 employees, 3 branches and a registered capital of RMB 58.83 milion,the company is a strateaic partner of labil, B80, Luxshare-CT,Flex, Amphenol, Bose, TE and other famous companies in providing vaious precision hardware products.

Factory building

Machinery and equipment

Production workshop

Product testing