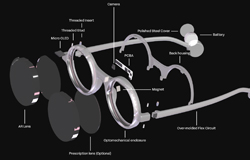

With the rapid development of augmented reality (AR) technology, more and more companies are beginning to pay attention to the design and production of AR glasses. As a core component of AR devices, glasses frames need to provide not only a comfortable wearing experience, but also high strength, lightness and good durability. Therefore, lightweight magnesium alloy materials have gradually become the preferred material for designing AR glasses frames. In the process of customizing magnesium alloy AR glasses frame components, it is particularly important to choose a trustworthy supplier. JARKEL Casting is a leading magnesium alloy casting expert in the industry, focusing on providing customers with high-quality customized solutions. This article will explore why JARKEL Casting is chosen for customized lightweight magnesium alloy AR glasses frame components, how to improve product performance, and maximize customer satisfaction.

1. Advantages of lightweight magnesium alloys in AR glasses frames

The frame design of AR glasses must take into account the user's comfort and experience. Traditional metal materials are usually heavy and can easily cause discomfort when worn. As a lightweight metal, magnesium alloy has a lower density than aluminum and steel, which can significantly reduce the weight of the glasses frame, making it lighter to wear. The lightweight design can not only reduce the overall weight of the glasses, but also improve the wearing comfort, thereby enhancing the user experience.

2. Customized solutions of JARKEL Casting

JARKEL Casting focuses on magnesium alloy casting technology and has many years of experience in the field of precision casting. The company uses advanced technology and equipment to provide customized magnesium alloy AR glasses frame structural parts. JARKEL Casting's customized solutions cover the entire process from design to production, ensuring that every detail meets the customer's special needs.

Precise customization: JARKEL Casting provides high-precision customization services and can design magnesium alloy AR glasses frames that meet personalized standards according to the needs of different customers. Whether it is size, shape or surface treatment, JARKEL Casting can meet various requirements.

Diversified applications: JARKEL Casting's magnesium alloy AR glasses frame structural parts are not only suitable for AR glasses, but can also be widely used in other fields that require lightweight structural parts, such as sports glasses, smart glasses, etc.

High quality assurance: JARKEL Casting uses high-quality magnesium alloy materials and adopts a strict quality control process to ensure worry-free quality in every production link. Through the precision casting process, the magnesium alloy frame is ensured to have excellent strength, durability and corrosion resistance.

3. Physical properties and environmental adaptability of magnesium alloy

In the application of AR glasses, the frame needs to be able to withstand the impact and pressure in daily use. The strength and toughness of magnesium alloy make it an ideal material choice. Compared with other lightweight materials, magnesium alloy can provide better mechanical strength and impact resistance while maintaining lightness. Magnesium alloy has excellent corrosion resistance and can cope with various complex environmental conditions, including areas with high humidity or heavy salt spray.

4. How JARKEL Casting meets market demand

As AR technology continues to mature, the market demand for AR glasses is gradually increasing. Different consumer groups have different requirements for AR glasses, so customization has become an indispensable service. JARKEL Casting can provide the most suitable magnesium alloy AR glasses frame structural parts according to different design requirements, usage scenarios and production processes. Whether it is mass production or small batch customization, JARKEL Casting is able to complete orders efficiently and ensure that each product meets industry standards.

Global service: JARKEL Casting not only occupies an important position in the domestic market, but also provides high-quality customization services to customers around the world. No matter where the customer is located, JARKEL Casting is able to ensure on-time delivery through efficient production capacity and logistics systems.

Continuous innovation: JARKEL Casting has been committed to technological innovation and process improvement, and continuously improves product quality and production efficiency. The company has a strong R&D team that can quickly respond and launch innovative products according to market trends and customer needs.

5. JARKEL Casting's technical advantages in magnesium alloy casting

JARKEL Casting uses advanced casting technology to ensure the accuracy and strength of each component in the production process of magnesium alloy AR glasses frames. The company uses high-precision CNC machining equipment to finely process the castings to ensure that each frame meets strict dimensional requirements. In addition, JARKEL Casting also uses modern surface treatment technology to provide better corrosion resistance and aesthetic effects for magnesium alloy frames.

High-precision casting: Through precision casting technology, JARKEL Casting can produce precision parts that meet customer requirements, ensuring that every detail of the eyeglass frame is accurate.

Environmentally friendly production: JARKEL Casting pays attention to environmental protection, strictly abides by environmental regulations during the production process, uses recyclable materials, and minimizes the impact on the environment.

6. Why choose JARKEL Casting?

The reason for choosing JARKEL Casting is not only quality assurance, but also its highly customized service and reliable cooperation spirit. Whether you need to customize a new AR eyeglass frame or optimize the existing frame design, JARKEL Casting can provide professional solutions to ensure that your product stands out in the market.

Efficient delivery: JARKEL Casting has a strong production capacity and can complete a large number of customized requirements in a short time to ensure on-time delivery.

Flexible customization: Whether it is mass production or small batch customization, JARKEL Casting can provide flexible solutions according to customer needs.

Strong technical support: JARKEL Casting has a highly skilled team that can provide full technical support and advice during the design and production process.

Conclusion

With the continuous development of AR technology, the lightweight and high-strength requirements of AR glasses frames are also increasing. Choosing JARKEL Casting to provide customized lightweight magnesium alloy AR glasses frame structural parts can not only ensure the high performance and comfort of the glasses, but also give your products a dominant position in the market. With its leading technology, rich experience and efficient service, JARKEL Casting has become the preferred partner of many AR technology companies and glasses manufacturers. If you are looking for high-quality magnesium alloy AR glasses frame structural parts, JARKEL Casting is undoubtedly your ideal choice.

Home

Home admin

admin  Feb 24,2025

Feb 24,2025

Why do the world's top 5 AR brands choose JARKEL Casting's magnesium alloy structural parts? Revealing the manufacturing code of lightweight AR glasses

Why do the world's top 5 AR brands choose JARKEL Casting's magnesium alloy structural parts? Revealing the manufacturing code of lightweight AR glasses