With the rapid development of augmented reality (AR) technology, AR glasses have gradually become one of the representatives of future technology products. In the design and manufacture of AR glasses, the choice of materials is crucial. Especially in the structural parts, choosing the right material can not only improve the performance of the glasses, but also reduce weight and improve comfort. So why is magnesium alloy the preferred material for AR glasses structural parts? Today, JARKEL Casting will give you an in-depth interpretation of the advantages of magnesium alloy in AR glasses and its application prospects.

1. The unique advantages of magnesium alloy: lightness and high strength

As a wearable device, one of the core characteristics of AR glasses is lightness. When users wear them, comfort is crucial. Overweight glasses not only affect the user experience, but also may cause discomfort when wearing. Magnesium alloy has a very light weight, and its density is 33% lower than aluminum and 75% lower than steel. Therefore, using magnesium alloy in the structural parts of AR glasses can significantly reduce the overall weight.

At the same time, magnesium alloy is not only light, but also has high strength. As a metal alloy, magnesium alloy has excellent performance in compression and bending resistance, and can effectively protect the internal electronic equipment and display screen of AR glasses from external impact.

2. Corrosion resistance and durability of magnesium alloy

In daily use, AR glasses will inevitably be exposed to various factors in the environment, such as sweat, dust and different climatic conditions. Magnesium alloy has strong corrosion resistance, especially after surface treatment, its durability and oxidation resistance are more outstanding. This means that magnesium alloy AR glasses structural parts can not only maintain their appearance and function for a long time, but also continue to work in various harsh environments.

3. Design flexibility of magnesium alloy and AR glasses

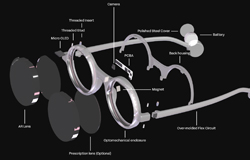

The structural parts of AR glasses need to meet the design requirements of different forms and functions, and magnesium alloys can be processed into various complex shapes through casting, extrusion and other processes due to their excellent plasticity. This provides more freedom for designers of AR glasses, which can better achieve fine control of appearance and structure, and design more exquisite and thin AR glasses.

4. JARKEL Casting's magnesium alloy AR glasses structural parts solution

As a leading company in the field of magnesium alloy casting, JARKEL Casting is committed to providing high-quality magnesium alloy structural parts for AR glasses manufacturers. We use advanced casting processes and strict quality control systems to ensure that every product meets high standards. Whether it is small batch customization or large-scale production, JARKEL Casting can provide flexible solutions based on the specific needs of customers.

High-precision casting technology

JARKEL Casting has advanced high-precision casting technology, which can process magnesium alloys into structural parts with precise dimensions and smooth surfaces, reducing the need for secondary processing and improving production efficiency. At the same time, our technical team can also customize according to customer requirements to ensure that every detail meets strict design standards.

Professional surface treatment

We provide a variety of surface treatment processes for magnesium alloy structural parts, including anodizing, electroplating, etc., to further improve the corrosion resistance and oxidation resistance of magnesium alloys, ensuring that the product still maintains excellent performance and appearance during long-term use.

5. Future Prospects of Magnesium Alloy AR Glasses Structural Parts

With the advancement of technology, AR glasses will not only be a tool for entertainment and games, but will also be widely used in education, medical care, industry and other fields. Therefore, the requirements for the structural parts of AR glasses will become higher and higher, especially in terms of lightweight, durability and comfort. Magnesium alloy, as a material with great potential, will play an increasingly important role in the manufacture of AR glasses.

JARKEL Casting will continue to focus on the research and development and innovation of magnesium alloy technology, provide high-quality AR glasses structural parts to global customers, and promote the development of technology.

6. Why choose JARKEL Casting?

Choosing JARKEL Casting, you are not just choosing a supplier, but a reliable partner. We are committed to providing the most professional service to every customer, ensuring that every link of the product from design to production can meet the best quality standards. With many years of industry experience, our magnesium alloy AR glasses structural parts will help your products stand out in the market.

Global Manufacturing Capabilities

JARKEL Casting not only has a wide range of customers in China, but also has a strong production capacity and excellent quality control. Our magnesium alloy structural parts have been successfully exported to many countries and regions, and are deeply trusted and praised by customers.

Efficient Customer Service

We understand that customer needs are changeable, so we provide flexible customization services to help customers achieve personalized design. At the same time, JARKEL Casting has a professional customer service team to provide technical support and after-sales service to customers at any time to ensure the smooth progress of each order.

Choose JARKEL Casting and walk at the forefront of technology

With the continuous development of AR glasses technology, choosing the right material has become one of the key factors for companies to compete in the market. Magnesium alloy has become the only choice for AR glasses structural parts due to its light, strong and durable characteristics. As a leader in the field of magnesium alloy casting, JARKEL Casting is helping global customers build lighter, stronger and more durable AR glasses with its superb technology and high-quality products.

If you are looking for a supplier of magnesium alloy AR glasses structural parts, JARKEL Casting will be your ideal choice. Contact us and let us promote the future of technology together.

Home

Home admin

admin  Feb 25,2025

Feb 25,2025

Why do the world's top 5 AR brands choose JARKEL Casting's magnesium alloy structural parts? Revealing the manufacturing code of lightweight AR glasses

Why do the world's top 5 AR brands choose JARKEL Casting's magnesium alloy structural parts? Revealing the manufacturing code of lightweight AR glasses