As the augmented reality (AR) industry continues to grow, the demand for high-quality AR glasses frames made from lightweight and durable materials like magnesium alloy is on the rise. Choosing the right factory to manufacture these frames is crucial for ensuring product quality, meeting deadlines, and staying competitive. In this article, we’ll explore the key factors to consider when selecting a magnesium alloy AR glasses frame factory and highlight why JARKEL Casting is the ideal partner for your manufacturing needs.

Why Magnesium Alloy for AR Glasses Frames?

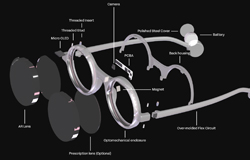

Magnesium alloy has become the material of choice for AR glasses frames due to its exceptional properties:

Lightweight: Magnesium alloy is 33% lighter than aluminum, making it ideal for comfortable, long-term wear.

High Strength: Despite its light weight, it offers excellent durability and resilience.

Corrosion Resistance: Magnesium alloy is highly resistant to corrosion, ensuring the longevity of the frames.

Thermal Conductivity: It dissipates heat effectively, protecting the sensitive components of AR glasses.

Customizability: Magnesium alloy can be molded into complex shapes, allowing for innovative and ergonomic designs.

These properties make magnesium alloy the perfect material for AR glasses frames, but the success of your product also depends on choosing the right factory for manufacturing.

Key Factors to Consider When Choosing a Factory

Selecting the right magnesium alloy AR glasses frame factory requires careful evaluation of several factors:

Experience and Expertise

A factory with a proven track record in magnesium alloy casting is essential. Look for manufacturers with experience in producing precision components, especially for high-tech industries like AR.

Advanced Manufacturing Technology

The factory should utilize state-of-the-art technologies, such as CNC machining, 3D modeling, and precision casting, to ensure high-quality production.

Customization Capabilities

The ability to create custom designs tailored to your specific needs is crucial. The factory should offer flexibility in design, finish, and branding options.

Quality Control Standards

Rigorous quality control processes are essential to ensure that every frame meets industry standards. Look for factories with certifications like ISO 9001.

Scalability and Production Capacity

The factory should be able to handle both small prototype orders and large-scale production to accommodate your business growth.

Sustainable Practices

A commitment to eco-friendly manufacturing processes and sustainable material sourcing is increasingly important in today’s market.

Global Reach and Logistics

If you’re operating internationally, choose a factory with a robust logistics network to ensure timely delivery of your products.

Why Choose JARKEL Casting as Your Magnesium Alloy AR Glasses Frame Factory?

JARKEL Casting is a trusted name in the magnesium alloy manufacturing industry, offering exceptional services and expertise. Here’s why they stand out:

Decades of Experience

With years of experience in precision casting, JARKEL Casting has developed a deep understanding of magnesium alloy manufacturing. Their expertise ensures high-quality products that meet the demands of the AR industry.

Advanced Manufacturing Technologies

JARKEL Casting employs cutting-edge technologies, including CNC machining and 3D modeling, to produce precise and intricate frames. Their state-of-the-art facilities enable them to deliver complex designs with unmatched accuracy.

Comprehensive Customization Options

From design to finishing, JARKEL Casting offers a wide range of customization options. Whether you need a sleek, minimalist frame or a bold, innovative design, they can bring your vision to life.

Rigorous Quality Assurance

Every frame undergoes stringent quality control checks to ensure it meets the highest industry standards. JARKEL Casting’s commitment to quality has earned them a reputation for reliability and excellence.

Scalable Production Capacity

JARKEL Casting can handle both small-scale prototype orders and large-scale production, making them a versatile partner for businesses of all sizes.

Sustainable Manufacturing Practices

JARKEL Casting is dedicated to sustainability. They use eco-friendly manufacturing processes and source materials responsibly, minimizing their environmental impact.

Global Reach and Timely Delivery

With a global customer base, JARKEL Casting has the infrastructure and logistics network to deliver frames to clients worldwide. Their efficient processes ensure timely delivery, no matter where you are located.

Applications of JARKEL Casting’s Magnesium Alloy AR Glasses Frames

JARKEL Casting’s magnesium alloy frames are used in a wide range of applications, including:

Consumer AR Glasses

Lightweight and stylish frames enhance the user experience for everyday AR glasses users.

Industrial AR Glasses

Durable and ergonomic frames are ideal for industrial applications, where AR glasses are used in demanding environments.

Medical AR Glasses

Precision-engineered frames support medical professionals in performing complex procedures with AR-assisted technology.

Gaming AR Glasses

Custom designs cater to the needs of gamers, providing comfort and style during extended gaming sessions.

The Future of Magnesium Alloy AR Glasses Frames

As the AR industry continues to grow, the demand for high-performance and customizable glasses frames will only increase. Magnesium alloy, with its unparalleled properties, is poised to remain the material of choice for AR glasses frames. JARKEL Casting is at the forefront of this industry, leveraging its expertise and technology to deliver cutting-edge solutions.

Why Partner with JARKEL Casting?

Choosing the right factory is crucial for the success of your AR glasses. Here’s why JARKEL Casting is the ideal partner:

Proven Track Record: With a history of delivering high-quality products, JARKEL Casting has earned the trust of clients worldwide.

Innovative Solutions: Their team of experts is dedicated to pushing the boundaries of what’s possible with magnesium alloy.

Customer-Centric Approach: JARKEL Casting works closely with clients to understand their needs and deliver tailored solutions.

Whether you’re a startup or an established brand, JARKEL Casting has the expertise and resources to help you succeed in the competitive AR glasses market.

Choosing the right magnesium alloy AR glasses frame factory is a critical decision that can impact the success of your product. With their expertise, advanced technology, and commitment to quality, JARKEL Casting is the ideal partner for businesses looking to create innovative and high-performance AR glasses frames. If you’re ready to take your AR glasses to the next level, partner with JARKEL Casting and experience the difference that custom magnesium alloy frames can make.

Home

Home admin

admin  Feb 18,2025

Feb 18,2025

How to Choose the Best Magnesium Alloy AR Glasses Frame Manufacturer in China? Why JARKEL Casting is the Top Choice

How to Choose the Best Magnesium Alloy AR Glasses Frame Manufacturer in China? Why JARKEL Casting is the Top Choice