As augmented reality (AR) technology accelerates its penetration into the consumer electronics market, the lightweight, comfort and durability of AR glasses have become the core of user concern. As the "skeleton" of AR glasses, AR glasses frame material directly determines the user experience and market competitiveness of the product. JARKEL Casting is leading the innovation in this field with its customized magnesium alloy AR glasses frame technology.

1. Magnesium alloy: the ultimate answer to lightweight AR glasses

The perfect balance of weight and strength

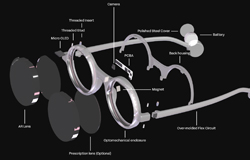

The density of magnesium alloy is only 1.8g/cm³, which is 2/3 of aluminum and 1/4 of steel, but it can provide higher specific strength. Taking Meta's Orion AR glasses as an example, its magnesium alloy frame weighs only 98 grams, taking into account both lightness and durability, greatly improving the comfort of long-term wearing7. JARKEL Casting further controls the weight of the magnesium alloy frame to 30-50 grams through precision casting technology to meet the lightweight needs of consumer-grade AR glasses.

Revolutionary improvement in heat dissipation performance

The high-performance processors and optical modules (such as Micro OLED displays and optical waveguide technology) of AR glasses are prone to generate heat during operation, and traditional plastic frames are difficult to dissipate heat effectively. The thermal conductivity of magnesium alloy is 300 times that of plastic, which can quickly dissipate heat, avoid performance reduction problems caused by overheating of the equipment, and extend the service life

Impact resistance and environmental adaptability

Magnesium alloy has excellent damping performance, can absorb vibration and impact, and protect precision optical components (such as cameras and sensors) from damage. At the same time, JARKEL Casting's patented surface treatment technology gives magnesium alloy frames corrosion resistance and scratch resistance, which is suitable for outdoor, industrial and other scenarios

II. JARKEL Casting's core technology: customized magnesium alloy solutions

Precision die-casting process

JARKEL uses semi-solid die-casting (Thixomolding) technology to achieve integrated molding of complex structures of magnesium alloy frames. For example, it supports the embedded design of camera modules and sensor arrays in AR glasses, reduces assembly links and improves structural stability

Surface treatment innovation

For the fashionable attributes of AR glasses, JARKEL has developed a micro-arc oxidation (MAO) process, which can form a ceramic coating on the surface of magnesium alloy, providing matte, metallic luster or color coating effects to meet the personalized design needs of brand owners

III. Industry application: from consumer electronics to industrial scenarios

Industrial and medical fields: functionality first

In industrial inspection scenarios, JARKEL's magnesium alloy frame can integrate high-temperature resistant coatings and dustproof structures, and with the AI recognition function of AR glasses (such as voice interaction driven by ChatGPT), remote expert collaboration and real-time data analysis can be achieved

Future trend: AR-driven personalized framework

Through AI algorithm analysis of user facial data, JARKEL can customize magnesium alloy frames that fit different face shapes, and optimize pressure distribution combined with sensor data to avoid the "nose bridge pressure" pain point of traditional glasses

IV. Challenges and future prospects

Although the advantages of magnesium alloy frames are significant, their cost is still higher than plastic and some aluminum alloy solutions. JARKEL is reducing the unit price through large-scale production and recycling technology, aiming to control the cost within the acceptable range of consumer-grade AR glasses in 2026. In addition, with the popularization of diffraction waveguide and Micro LED display technology, the "lightweight + high performance" combination of magnesium alloy frames will become the standard for AR glasses

Conclusion: Redefining the possibility of AR glasses

JARKEL Casting's customized magnesium alloy frame not only solves the lightweight problem of AR glasses, but also sets a new benchmark for the industry through material innovation and intelligent manufacturing. In the future, with the deep integration of 5G, AI and AR technologies, magnesium alloy frames will become the core carrier connecting virtual and reality, pushing humans into the "unconscious" smart wearable era.

Home

Home admin

admin  Feb 18,2025

Feb 18,2025

Why is JARKEL Casting Leading the Custom Magnesium Alloy AR Glasses Frame Industry?

Why is JARKEL Casting Leading the Custom Magnesium Alloy AR Glasses Frame Industry?